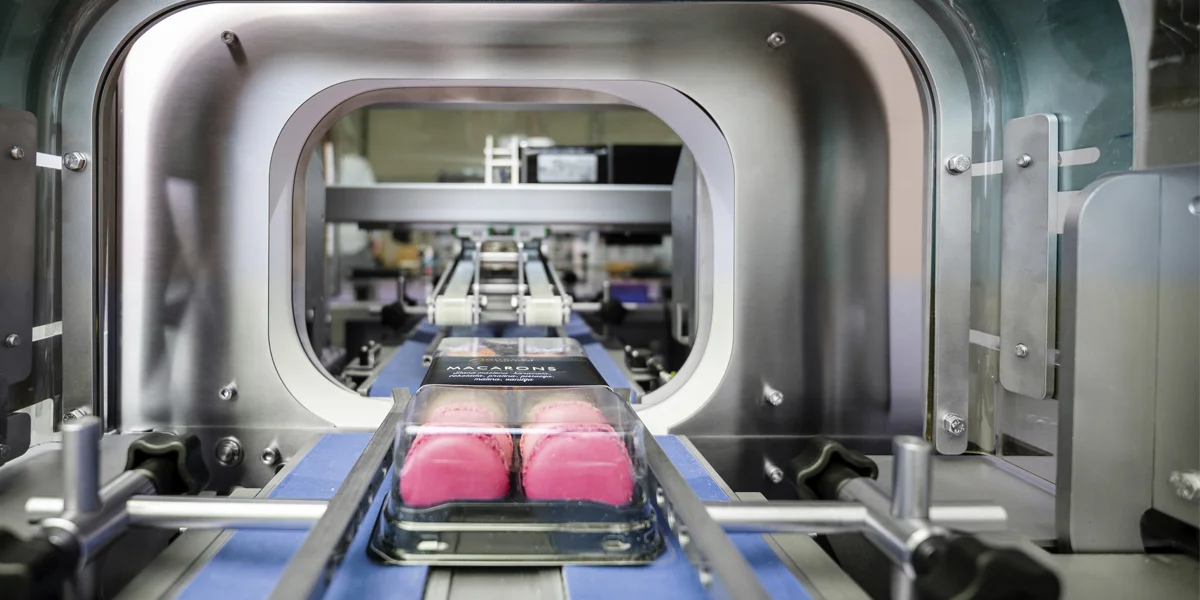

Fully automatic banding machines

Our fully automatic banding machines are designed for high production volumes and higher speeds in automated processes. Depending on your product specifications and the way in which the product must be guided to the banding arch, Bandall offers four basic models that each individually can be developed further as specials, multi-head machines and other fully automated tailor-made configurations.

Bandall TXL

Product feed-through with powered top and bottom transport belts for more speed and precision.

Bandall TRL

Products are being transported in a linear set-up.

Bandall TRC

Infeed with a corner set-up, the product is rotated 90 degrees before going into the banding arch.

Bandall TRB

Infeed and outfeed line with independently driven conveyor belts.

The ultimate in speed and precision

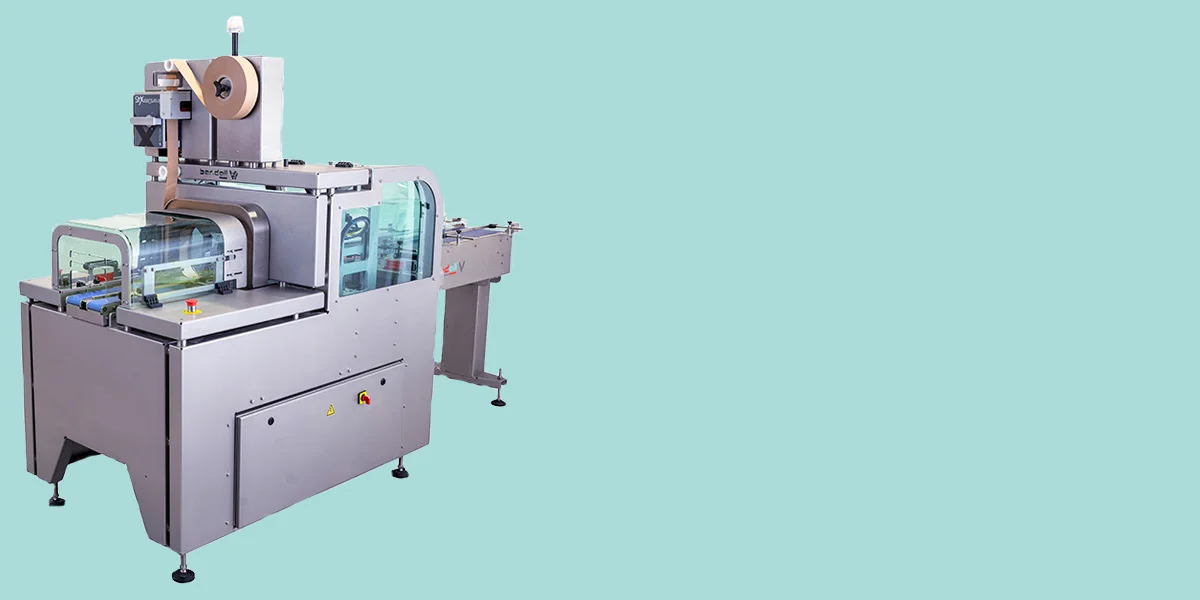

The Bandall V-series

This renewed line has been developed for even higher production speeds, precision, flexibility, and accessibility. High quality control technology, combined with Servo techniques, lead to banding speeds of 40 bands per minute, or more.

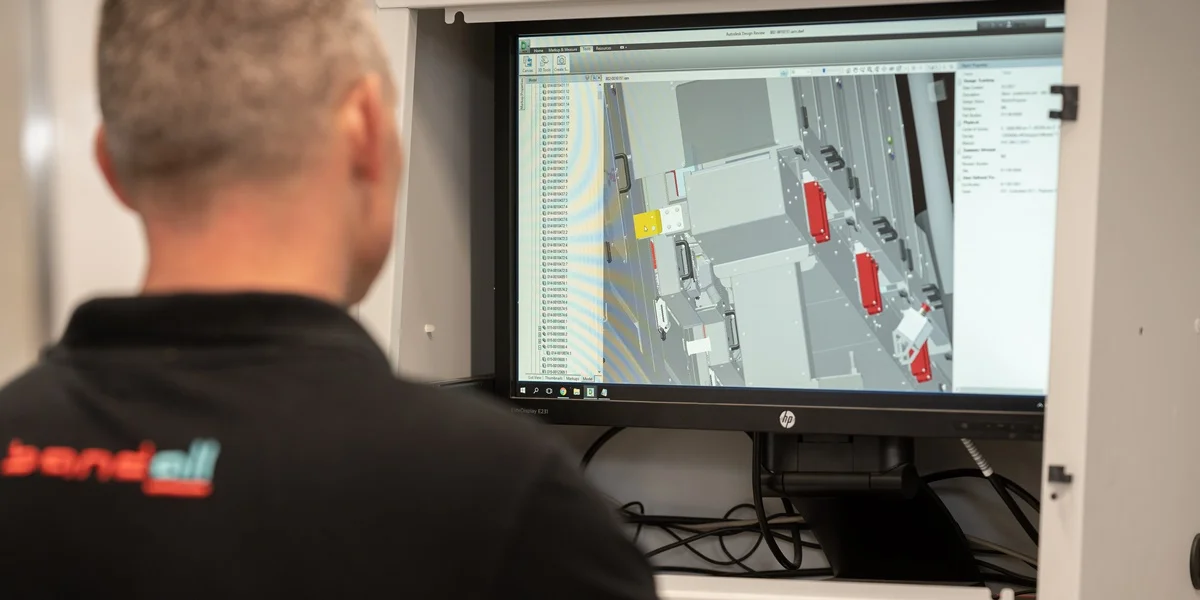

Tailor-made automatic banding machines

We build your fully automatic banding machine on the foundation of the standard machine, based on various standardized sizes and modules. From there, the machines can further be customized, depending on how your product must be guided through the banding process.

Fully automatic banding solutions

Functional (servo-driven) pushers ensure a perfect positioning towards the banding arch. In addition, various infeed and outfeed options are available, such as powered roller conveyors, food grade conveyor belts, etc.

A wide range of options

You can expand each Bandall automatic banding machine with a wide range of options, such as printers, stackers, press, etc. Your product and process specifications are always leading and can generate various customized solutions. It is possible that the speed at which your products leave your production process is a reason to offer a multi-head version. This allows even higher production speeds to be achieved.

Looking for an automatic banding machine?

Leave your contact details here and one of our advisors will get in touch!