Stacking and bundling machines

Bandall offers various possibilities for the fully automatic stacking and bundling of products using only one machine. Whether you’re stacking and bundling 2, 3, or 7 products, big or small, Bandall offers the right solution. From standardized to fully automatic and customized multi-head machines.

Fully automatic bundling

Of course, you are also able to stack and bundle semi-automatically using our Stand Alone machine. For large production volumes, we offer various fully automated stacking and bundling solutions. For even larger production volumes and speeds, we also offer multi-head bundling machines. Which solution fits your situation best, depends on your product and process specifications.

Fast and efficient bundling

The V-TRC-ST is perfect for the fast and efficient bundling of small boxes. It can handle up to 240 boxes per minute, so it is ideal for high production capacities and speeds. The machine comes with an interchangeable banding arch, meaning you can change band widths on the same bundling machine. This also allows for easy maintenance.

Using as little packaging material as possible

The compact TRL-ST stacking and bundling machine is very suitable for making multipacks quickly and fully automatically using as little packaging material as possible. This machine is equipped with a short infeed line and an integrated stacking unit, and is suitable for a large range of product sizes. The end result is a firmly bundled stack of flat boxes, thermoformed packaging, or flow packs. Ideal for Retail Ready Packaging or promotional packaging.

Why bundle with Bandall?

• Compact and flexible

• Fast and budget-friendly

• Fully automated infeed and outfeed

• Different product sizes possible

• Easy to adjust

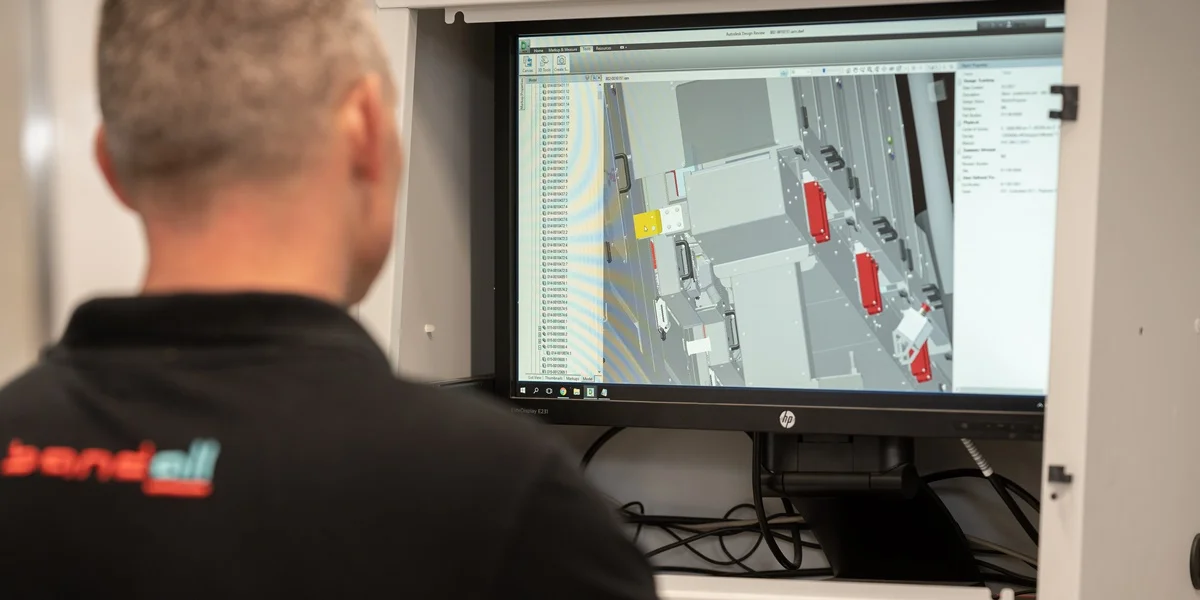

A multi-head machine for the highest speeds

If the products leave your production process at high speeds, we may recommend a multi-head machine. These bundling machines divide the supply over several lines, with each line having its own stacking unit and banding head. The machines can be made with two, three, four, or even five heads. These are often standardized and proven technologies, combined with product-specific customization.

Unique benefits

- Very high production capacities possible

- Guaranteed stable bundles

- Fully automatic infeed and outfeed

- Easy to adjust

- Available with various printer options for variable prints

- All benefits of the unique band feed-through system

Crosswise bundling for additional sturdiness

In some cases - often for logistical reasons - product bundles require additional sturdiness. Crosswise banding could be an option in such a case. Immediate benefits include:

- Less packaging material compared to shrink film

- Optimal transport efficiency

- Extra strong bundles

- Excellent references worldwide

Our banding machines:

Tailor made banding machines

Multi-head banding machines

Fully automatic banding machines

Looking for a stacking and bundling machine?